Basketweave Coil

Winder

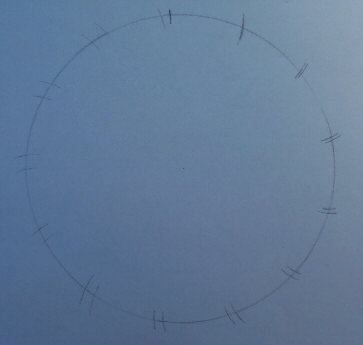

Start with a layout on a sheet of paper.

Layout on a sheet of paper a 6" circle with a compass.

Use the compass to devide the circle into 13 equal apaces

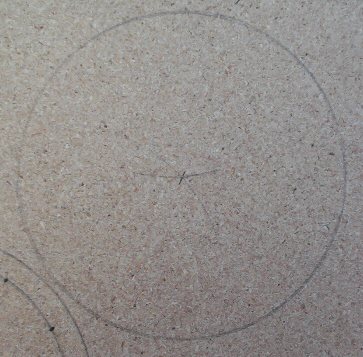

Transfer the layout to the wood. Make a larger circle (7")

around

it.

That is where you will cut.

Make another 7" circle layout.

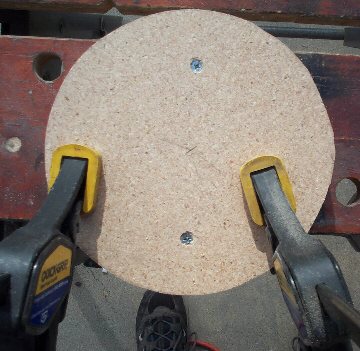

Cut the two circles out.

Clamp them togeather with some glue in between, and put a

couple

of flathead screws in to hold.

Make the screws flush or below the surface.

You can sand them down to make them even if you like, but it

is

not nessasary.

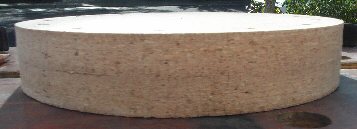

Drill out the 1/8" holes, but don't go all the way through.

I used a drill press, but if you are very careful you can use

a

hand drill.

It is very important that the holes be straight into the wood.

Drill out the center to clear the bolt you are using (3/8"

fine

thread bolt).

I used a bronze bearing, but it is not nessasary.

Drill out your base board to clear the bolts you are using.

Place bolt (3/8" x 2 1/2" fine thread) in base, then a fender

washer,

then the wheel, then another fender washer on top of the wheel,

followed by a locking nut. You can tighten up the bolt untill

the

wheels just "drags" a little, not too much!

The wire spindle is just a bolt and a nut on the top side.

I eliminated the rubber washer shown above. Just didn't need

it.

I put a couple of rubber feet on all four corners of the

bottom

to clear the bolt heads underneath.

This way it won't rock on the table. You could use wood block

just

as easy.

Insert the 1/8 fiberglass rods in and you are complete.There

are

a couple of improvements I made such as

#1 On top of the spool of wire I placed a fender washer, a

spring,

and a knob to put tension on the wire spool so it won't birdcase or

explode.

#2 I put staples in the side of the coil winder wheel to

start

the wire in.

After you get to where you think is enough turns, I put my

meter

on the coil and take a reading to see where I am.

Move the coil up on the fiberglass rods so you can tie it

with

waxed

dental floss or you can hot glue it.

After the coil is secured, pull the rods up out of the wood to

release

the coil from the winder.

The fiberglass rods should be replaced with 1/8" styrene

tubes.

This will help keep the Q higher on your coil.

This can be done by just pushing the fiberglass rods out with

the

styrene tubes.

After you are done, you can straighten the windings up. That

will

also help the Q.