The horn or "bell" was missing a section from the edge.

A mold was made of a "good" section of the rim and used to

pour

a section that was missing.

(see above)

The base had severe cracks that ran all the way through to

the

inside.

In some spots I'm not sure what was holding it together.

The cracks were stabilized by filling with epoxy that was made

for

metal.

The base was "distorted" at the cracks and had to be smoothed

back

down.

The entire base was spun on a lathe to smooth the epoxy and

cracks.

A mold was made of a "good" section of the rim, and was used

to

pour a section of the rim that was missing.

(see photo above)

Results

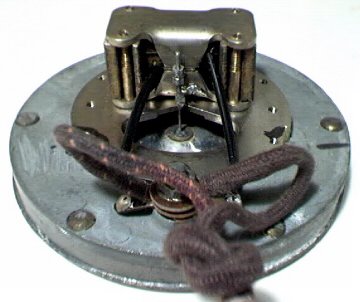

Interior

The interior was much worse that the exterior.

The coil was "open" (had a break in the windings) and the

armature

was very rusted and could not be saved.

I only regret that I did not take any photos before I started

work.

I was able to save the diaphragm section of the driver which

was

very large (about 3").

I used the interior of a USI military sound powered element to

drive

the diaphragm ("ear" element).

This element was left over from another restoration and it was

missing

a diaphragm, so it was a perfect match !!!

The upper part of the rod connecting them is from a RCA

military

sound powered element.

The results were that this horn can now work on a crystal

radio

because

it is much more efficient than the original Balanced Armature

setup.

Not real loud in my area because of a lack of a very strong

local

station, but OK.

It also will work very well with a single tube

battery

radio

such as a Westinghouse Aeriola Senior without an amplifier.

Compleated Horn